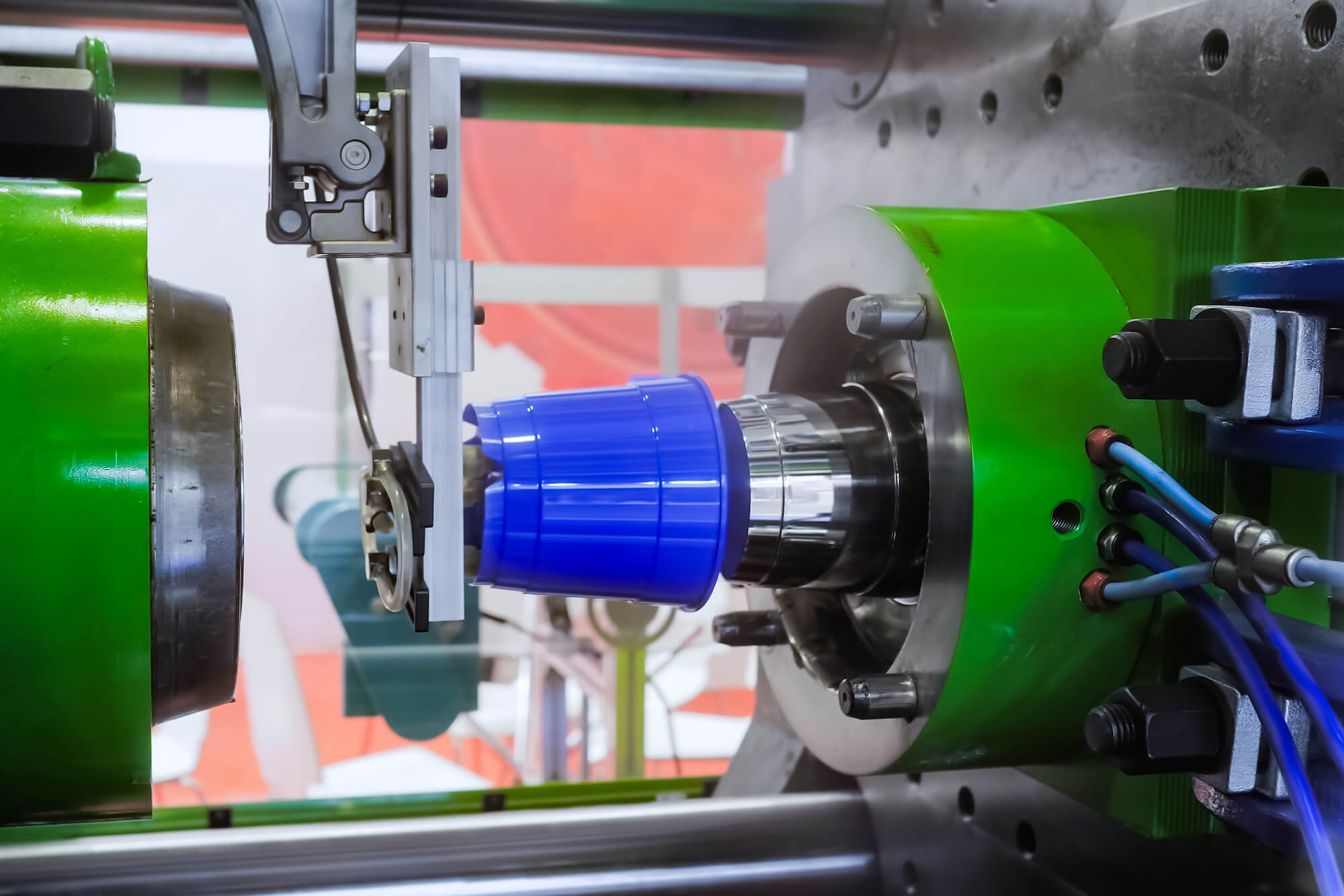

injection moulding

Custom plastic components, manufactured with precision and consistency

When you need plastic parts manufactured at scale, injection moulding is often the most efficient and reliable solution. At Talisman Group, we provide UK‑based injection moulding services that give you durable, cost‑effective components tailored to your exact requirements.

With press capabilities ranging from 25 to 1,100 tonnes of clamping pressure, we can manufacture everything from small precision parts to moulded products over one square metre. You can depend on consistent quality, responsive service and a production process designed around your needs.

Our advanced equipment ensures efficient, reliable production for businesses of all sizes. Utilising press capabilities range from 25 to 1,100 tonnes of clamping pressure, allows us to manufacture everything from the smallest injection-moulded components to large parts exceeding one square meter in size.

To optimize efficiency and reduce production costs, we employ programmable controllers for precise process control, as well as auxiliary equipment such as robots and sprue pickers. With UK-based facilities, we offer a responsive, cost-effective solution for all your injection moulding needs.

Why injection moulding works for your business

Injection moulding is one of the most widely used manufacturing methods for plastic components, and for good reason. It combines speed, repeatability and flexibility in a way that few other processes can match. Once your mould is created, we can produce thousands (or even millions) of identical parts with minimal variation. This makes it ideal if your business needs:

- High‑volume production without compromising on quality.

- Complex designs that would be difficult or costly to achieve with other methods.

- Versatile materials, from lightweight thermoplastics to heat‑resistant thermosets.

- Cost efficiency, thanks to reduced waste and optimised cycle times.

Injection moulding delivers shorter lead times, predictable costs and components that perform exactly as intended.

Thermoplastic and thermoset moulding

Choosing the right material is just as crucial as the moulding process itself. We support both thermoplastic and thermoset injection moulding, giving you flexibility depending on your application. Our team works with you to identify the right material for your project, balancing performance, appearance and cost.

Thermoplastic injection moulding

Ideal for parts that need to be lightweight, versatile and recyclable. These materials can be reheated and reshaped, making them suitable for a wide range of consumer goods, packaging and automotive components.

Thermoset injection moulding

Better suited to applications where strength, rigidity and heat resistance are essential. Thermoset plastics can’t be remelted, so they’re ideal for demanding environments such as electrical housings or industrial equipment.

Industries we support

Injection moulding is used across almost every sector, and our facilities are equipped to serve a wide range of industries. We can help your business bring products to market faster and with greater confidence by tailoring our approach to your sector and requirements:

- Electronic: Precision‑moulded components designed to meet the demanding standards of electrical and electronic applications, where accuracy and reliability are critical.

- Fluid transfer: Moulded solutions that withstand high temperatures, chemical exposure and visual requirements, supporting industries where performance and durability are essential.

- Automotive: Precision‑moulded components engineered for strength, consistency and compliance with the demanding performance and safety standards of the automotive sector.

- Rail: Robust, precision‑engineered mouldings designed to deliver long‑term reliability, safety and durability under the rigorous conditions of the rail industry.

- Other sectors: With over 85 years of technical moulding expertise, we also collaborate with businesses in emerging and specialist markets, adapting our processes to meet unique challenges.

Why choose Talisman Group?

Working with Talisman Group gives you access to more than just advanced machinery. You gain an experienced injection moulding partner who understands the pressures of modern manufacturing and the importance of reliable supply. Our goal is to make injection moulding a seamless part of your production strategy, so you can focus on growing your business. Here are some of the benefits of working with us:

- UK‑based production reduces shipping times and supply chain risks.

- Advanced programmable controllers deliver precise process control and consistent results.

- Capacity for small and large components gives you flexibility as your needs evolve.

- Responsive customer support ensures your project runs smoothly from design to delivery.

- Tailored solutions that balance performance, durability and cost for your specific applications.

- Decades of technical moulding experience underpin every project, giving you confidence in quality and delivery, no matter how complex.

Frequently asked questions

What is injection moulding?

Injection moulding is one of the most efficient ways to produce plastic components at scale, from everyday consumer products to specialist industrial components. It’s used across industries to create everything from small precision parts to large, moulded products over one square metre. The moulding process delivers consistent, repeatable results in high volumes, making it ideal for businesses that need reliability and cost efficiency.

How does the injection moulding process work?

Thermoplastic pellets are heated until molten, then injected into a custom‑designed mould under high pressure. Once cooled, the material solidifies into a durable, finished component. This method allows for complex shapes, tight tolerances and rapid production cycles, giving you design flexibility and scalability.

What materials can be used?

We specialise in thermoplastics, which soften when heated and solidify when cooled, making them versatile and recyclable. We also offer thermoset injection moulding, where the material permanently sets once cured. Thermoset parts are stronger and more heat‑resistant, making them suitable for demanding applications where durability is critical.

What size components can you manufacture?

Our press capabilities range from 25 to 1,100 tonnes of clamping pressure, which means we can produce everything from the smallest injection‑moulded components weighing just a few grams to large parts exceeding one square metre in size.

How do you ensure consistency and efficiency?

We use programmable controllers to maintain precise process control, supported by auxiliary equipment such as robots and sprue pickers. This combination reduces waste, optimises cycle times and ensures every part meets the same high standard.

Why choose Talisman Group for injection moulding?

With UK‑based facilities, you benefit from responsive local support, shorter lead times and cost‑effective production. Our expert team also brings decades of experience in mould design, carefully selecting tool steels, optimising heat treatment and applying plating processes to extend tool life and deliver the highest‑quality finishes.

Is injection moulding suitable for smaller production runs?

Yes, although the process is most cost‑effective at higher volumes, it can also be the right choice for smaller runs if your part design is complex or requires the precision and repeatability that injection moulding provides.

Let’s talk

If you’re looking for a trusted, UK-based injection moulding partner, Talisman Group is here to help. Get in touch to discuss your requirements and receive a tailored quote. Together, we’ll deliver the components you need on time, to specification and with the consistency your business depends on.