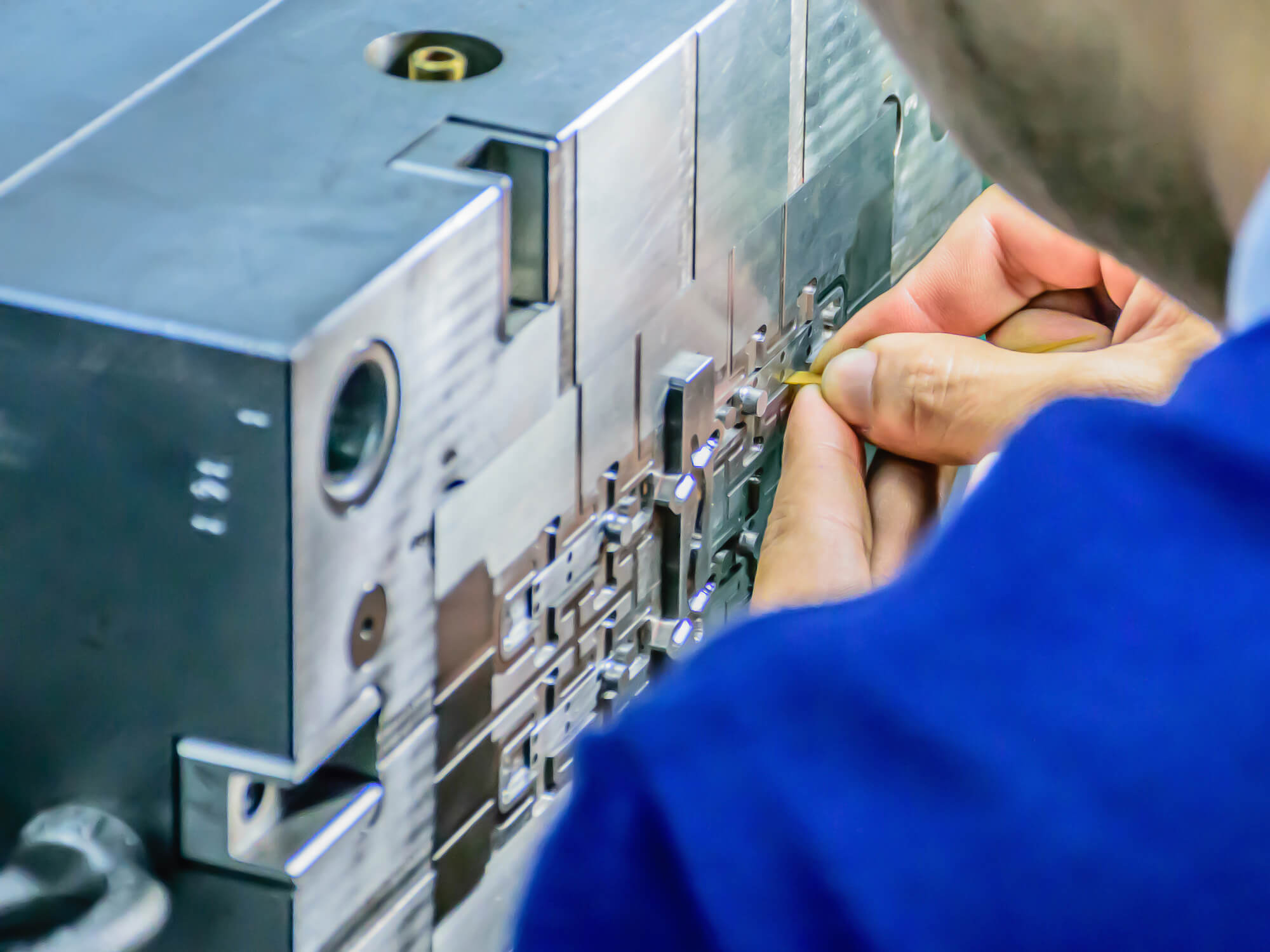

Design and Tooling

Precision tooling, designed for performance and reliability

Successful injection moulding projects start with the right tooling. At Talisman Group, we provide end‑to‑end tooling design and production services that help you achieve consistent quality, cost efficiency and dependable delivery. Based in the UK, our team combines decades of technical expertise with advanced CAD and 3D modelling technology to refine your designs before production begins. It means you get tooling that performs reliably, reduces downtime and supports your long‑term manufacturing strategy.

Why choose professional tooling design?

The quality of your moulding tool directly affects the performance of every component it produces. Well‑designed tooling reduces waste, shortens cycle times and ensures repeatable accuracy across multiple production runs. Our design and tooling solutions deliver:

- Design accuracy: Full CAD and 3D print modelling allow you to validate and refine your designs before committing to full production.

- Cost control: Early optimisation reduces the risk of expensive rework and delays.

- Material expertise: Our expert guidance on tool steels, coatings and inserts helps you achieve more durable results, so your budget goes further.

- Reliable outcomes: Our moulding tools are engineered to deliver consistent results across thousands of production cycles.

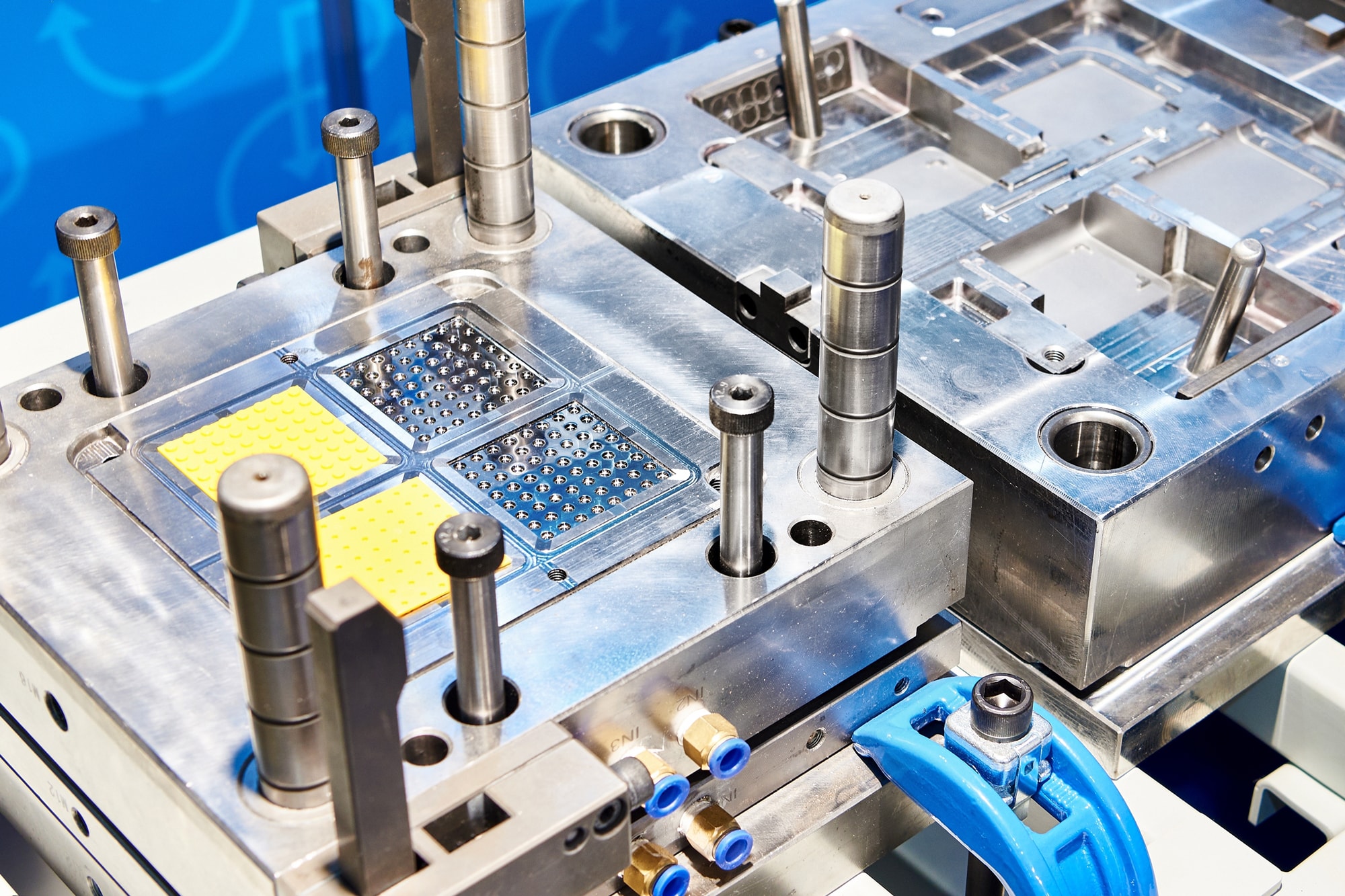

Tooling materials and processes

The right tooling solution depends on your component design, production volume and choice of materials. We work with trusted toolmakers in the UK, Europe and the Far East, selecting the best option for your needs. Combining advanced design methods with global sourcing means you benefit from tooling that is cost‑effective and built to last. Our process includes:

- CAD design and simulation to test component geometry and mould flow.

- 3D print modelling for rapid prototyping and design validation.

- Tooling material selection tailored to your production volumes and material abrasiveness.

- Rigorous testing and approval before tools are released for production.

Industries we support

Tooling design and production play a critical role in ensuring precision and reliability. Our global network of trusted toolmakers, combined with UK‑based expertise and project management, means you benefit from tooling that’s engineered to perform consistently in demanding environments. With our vast experience in CAD design, material selection and rigorous testing, you can be confident that your moulding tooling will meet strict quality standards while supporting cost‑effective, high‑quality production. The sectors we support include:

- Electronic: Precision tooling design for small, intricate components, with tight tolerances, controlled venting and reliable ejection to protect delicate geometries.

- Fluid transfer: Tooling engineered for chemically resistant materials and complex flow paths, optimising gate placement and cooling for stable, leak‑free parts.

- Automotive: Robust, multi‑cavity tooling built for repeatability and efficient cycle times, aligned with PPAP, material specs and OEM quality requirements.

- Rail: Durable tooling designed for large, high‑load components, with reinforced steel selections, wear‑resistant surfaces and consistent dimensional accuracy.

- Other sectors: Bespoke tooling tailored to specialist applications, to meet your performance targets.

Why choose Talisman Group?

Our goal is to make tooling design and production a seamless part of your manufacturing process. We can help you reduce risk, improve efficiency and gain confidence in every production run. We bring deep expertise in CAD modelling, material selection and tool validation, along with an understanding of the pressures faced by modern manufacturers. Here are some of the benefits of working with us:

- UK‑based project management with access to market-leading global tooling suppliers.

- Close collaboration to align tooling design with your business goals and budget.

- Access to trusted toolmakers in the UK, Europe and the Far East.

- Comprehensive testing and validation before your tooling is approved for production.

- Clear communication throughout the project, ensuring transparency and confidence.

- Decades of experience in plastic injection moulding and tooling design.

Frequently asked questions

What is tooling design?

Tooling design is the process of creating the moulds used to produce plastic components. Well‑designed tooling ensures accuracy, efficiency and consistent quality across production runs.

Where are your tools manufactured?

We source tools from trusted manufacturers in the UK, Europe and the Far East. Each tool is built to our specifications and approved only after rigorous testing.

How does CAD and 3D modelling improve tooling design?

CAD software and 3D print modelling allow you to test and refine designs before production. This reduces the risk of errors, shortens lead times and helps you make informed decisions about materials and processes.

How do you ensure tool quality?

Every tool undergoes a detailed review and testing process before release. We work closely with our suppliers and maintain clear communication throughout to ensure reliability.

Can you support both small and large projects?

Yes. Our expertise covers everything from single‑cavity tools for low‑volume runs to complex, multi‑cavity tools for large‑scale production.

What are the benefits of sourcing tooling through Talisman Group?

You gain access to global toolmaking expertise, backed by UK‑based project management and support. This combination gives you flexibility, cost efficiency and confidence in quality.

Do you only serve UK clients?

No. While our project management is UK‑based, we supply tooling solutions to businesses worldwide.

What turnaround times can I expect?

Lead times vary depending on complexity and sourcing location. With our established supplier network and responsive project management, we deliver efficient timelines without compromising quality.

Let’s talk

If you’re looking for a trusted UK partner for plastic injection moulding tooling design, Talisman Group is here to help. Get in touch to discuss your project and receive a tailored quote. Together, we’ll deliver the tooling you need, on time, to specification and built for long‑term performance.