Compression Moulding

Durable composite components, manufactured with precision and reliability

When your project demands strong, heat‑resistant, stable components, compression moulding is often the most effective solution. At Talisman Group, we provide UK‑based compression moulding services that deliver high‑quality thermoset and composite parts tailored to your exact specifications. From small electrical insulators to large, one‑piece railway carriage seats, you gain consistent results and dependable delivery from a team with decades of technical expertise.

Why choose compression moulding?

Compression moulding is a proven process for producing high‑strength plastic and composite components. By placing pre‑measured material into a heated mould and applying pressure, the material flows to fill the cavity and cures into a precise, durable shape. This method is particularly valuable when you need:

- Dimensional stability: Parts that resist warping, shrinking or expanding under heat and stress.

- Mechanical strength: Components that can withstand heavy use in demanding industrial environments.

- Fire resistance: Materials that meet strict safety standards.

- Cost efficiency: A competitive alternative to metal or die‑cast parts, especially for large or complex shapes.

For many industries, compression moulding offers the ideal balance of performance, durability and cost.

Compression moulding: materials and applications

Compression moulding is usually used with thermoset plastics and composites, which offer unique advantages over thermoplastics. Once cured, these materials can’t be remelted, giving them exceptional rigidity and heat resistance.

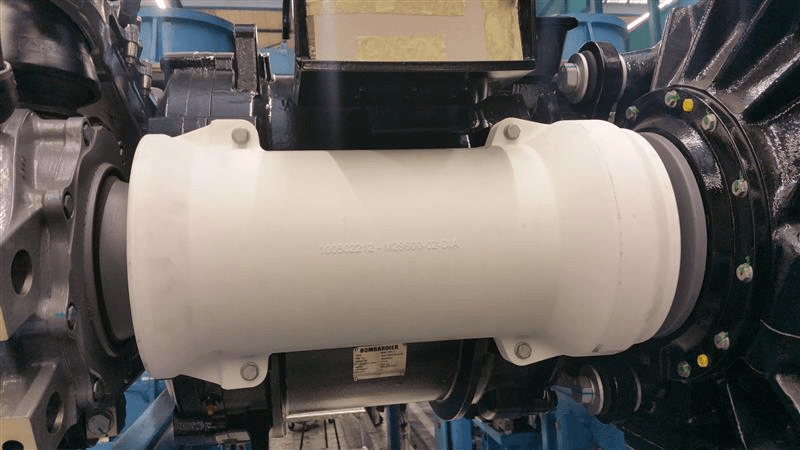

Typical applications include electrical housings and insulators, automotive and rail components, large structural parts where injection moulding would be impractical, and high‑strength, lightweight alternatives to metal castings. Selecting the right material for your application means you benefit from components that perform reliably in even the most challenging conditions.

Industries we support

Compression moulding is a proven solution across many demanding sectors. Our facilities are equipped to deliver lightweight, durable components that perform reliably in challenging environments. Our expertise gives you confidence in every application while helping you achieve cost‑effective, high‑quality results. The sectors we serve include:

- Electronic: Precision‑moulded insulators and housings that meet strict safety and performance standards.

- Fluid transfer: Components designed to withstand high temperatures, chemical exposure and demanding operating conditions.

- Automotive: Durable, high‑strength mouldings that comply with the rigorous quality expectations of the automotive sector.

- Rail: Robust, precision‑engineered parts that deliver long‑term reliability and safety in rail applications.

- Other sectors: With over 85 years of moulding expertise, we can adapt our processes to meet the unique requirements of specialist markets.

Why choose Talisman Group?

Our goal is to make compression moulding a seamless part of your production strategy, helping you reduce risk, improve reliability and bring durable products to market with confidence. We have deep expertise in composite materials and an understanding of the challenges faced by modern industries. Here are some of the benefits of choosing us:

- UK‑based production that reduces shipping times and supply chain risks.

- Advanced process control for consistent, repeatable results.

- Capability to produce both small precision parts and large, complex components.

- Responsive customer support from design through to delivery.

- Material expertise across thermosets and composites, ensuring the right balance of performance and cost.

- Decades of technical moulding experience, giving you confidence in quality and reliability.

Frequently asked questions

What is compression moulding?

Compression moulding is ideal for producing strong, heat‑resistant composite parts. We can use compression moulding to manufacture everything from small electronic insulators weighing just a few grams to large, one‑piece railway carriage seats weighing over 10kg. The process is especially valuable for components that need dimensional stability, fire resistance and long‑term durability.

How does compression moulding compare to injection moulding?

While injection moulding is often chosen for high‑volume thermoplastic parts, compression moulding excels with thermosets and composites. It allows for larger, more complex shapes without wall section limitations, making it a cost‑efficient alternative to metal or die‑cast components.

What equipment do you use?

Our facilities include a comprehensive range of presses, from 20-tonne to 450‑tonne clamp capacity, along with advanced side ram and transfer ram presses. This flexibility means we can adapt to diverse manufacturing requirements across multiple industries.

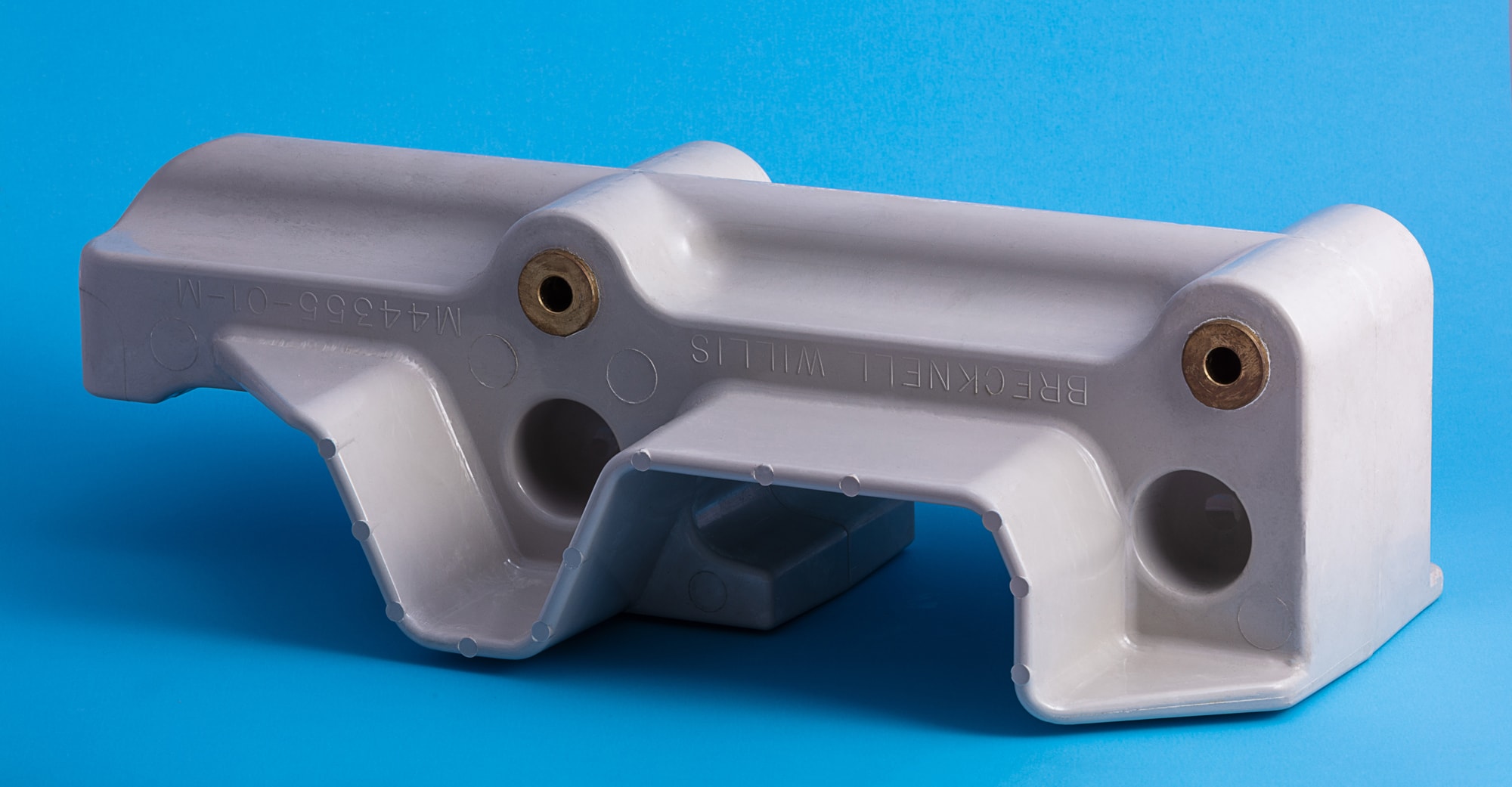

Can compression-moulded parts include inserts or colour options?

Yes. Threaded inserts can be moulded in during production or added post‑mould, depending on your requirements. We also offer a variety of colour options, subject to material type, so your components can meet your functional and aesthetic needs.

Why choose compression moulding for large components?

Unlike some other processes, compression moulding has no restrictions on wall section variations. This makes it uniquely suited to producing large structural, mechanical and insulating components that need to perform reliably under demanding conditions.

How durable are the mould tools?

Our mould toolings are precision‑engineered from steel and can be hardened or chrome‑plated to extend tool life. This ensures consistent quality across long production runs and reduces costs.

Do you only serve UK clients?

No. While our manufacturing is proudly UK‑based, giving local clients the advantage of shorter lead times and responsive support. We also supply compression-moulded components to businesses worldwide.

What turnaround times can I expect?

Because production is based in the UK and supported by a responsive local team, we can offer rapid turnaround times without compromising on quality. Lead times vary depending on the complexity and scale of your project, but efficiency and reliability are always at the core of our service.

Let’s talk

If you’re looking for a trusted UK partner for compression moulding, Talisman Group is here to help. Get in touch to discuss your requirements and receive a tailored quote. Together, we’ll deliver the composite components you need, on time, to specification, and with the consistency your business depends on.