Share

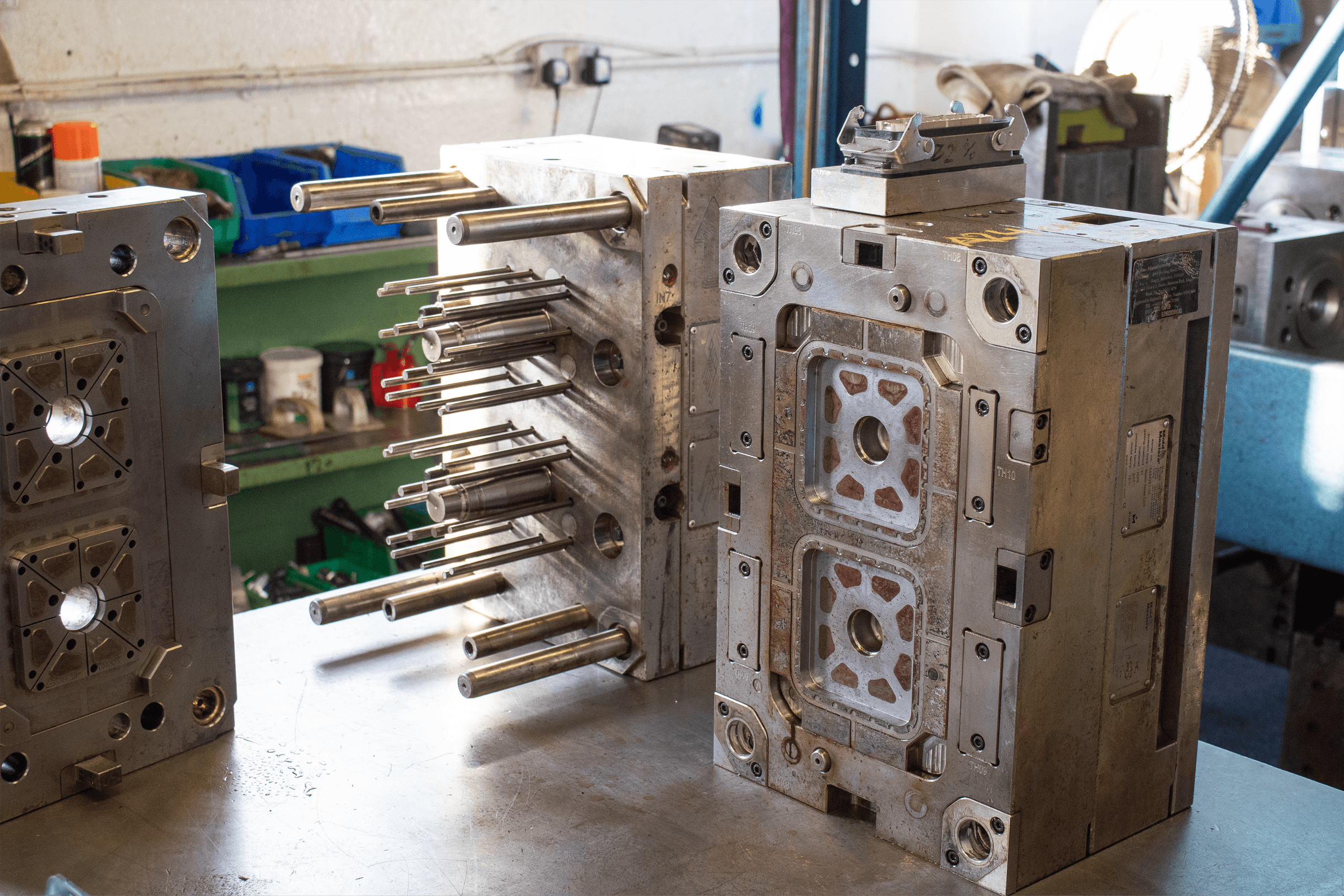

Inside the Tool Room

Inside the Tool Room

At Talisman Group, we offer a range of different specialist products and services to our customers, and one of those is our Design and Tooling service.

What is Tooling Design?

Tooling Design is the process of designing a Plastic Mould tool that will be used to mould Plastic Products. Every tool that runs through our tool rooms is unique, with our expert team of engineers working directly with customers to ensure that specifications are met. Appropriate tooling design ensures efficiency, accuracy, and consistent quality.

Tooling maintenance service provided by Talisman Group?

Cleaning

We have a dedicated team of engineers who will look after your tools and ensure that they are in the best condition possible before they go into our Injection Moulding machines. This is no simple process; we put our tools through rigorous inspections and testing following an extensive 16-stage checklist to make sure that every aspect of the tool is production ready.

Servicing

If, for whatever reason, one of our tools has fails our 16-stage inspection, we can rectify issues in-house in collaboration with the customer so that supply of product is not adversely affected.

Modifications

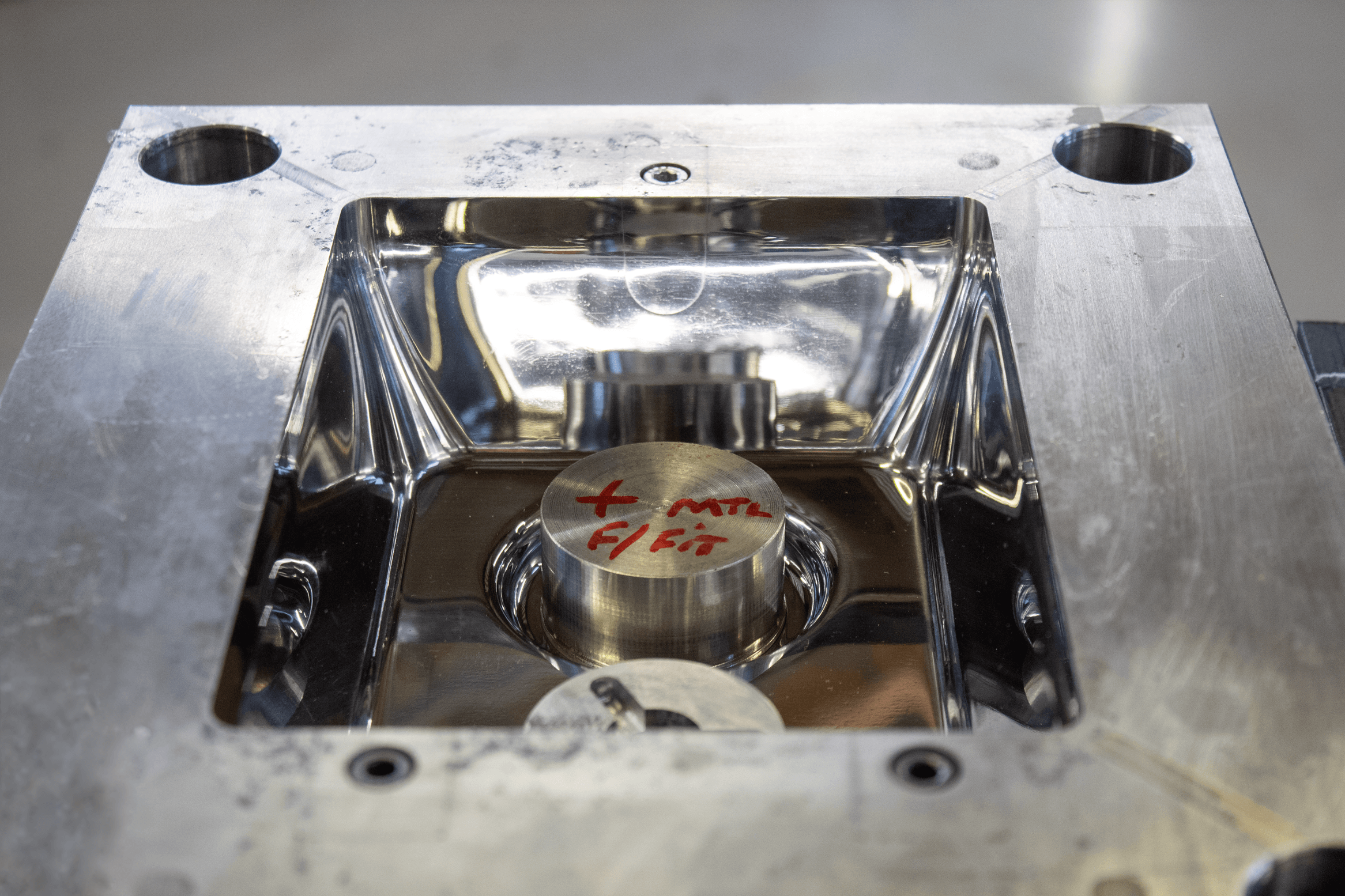

Our modifications service allows customers to make changes without the heavy financial burden. Over time, tooling can be subject to wear. Our engineers are experts in CAD, 3D Modelling, polishing and general tool upkeep, meaning your tooling investment is in safe hands.

At our Tool Room in Malvern, a customer came to us with a tool that required bringing back to life. It required new inserts and surface polishing to SPIA3. Our team used their CAD skills to modify the tool and bring the product back up to customer specifications. The tool was serviced and cleaned, and the result ended up looking like this:

If you are interested in developing new or existing tools, then please get in touch with us at: